Computer-controlled cutting

4AOL

Laser cutting machine safe operation precautions

1.Learn how to keep safety

2.Learn different kind of material which can be manufacture by laser cutter

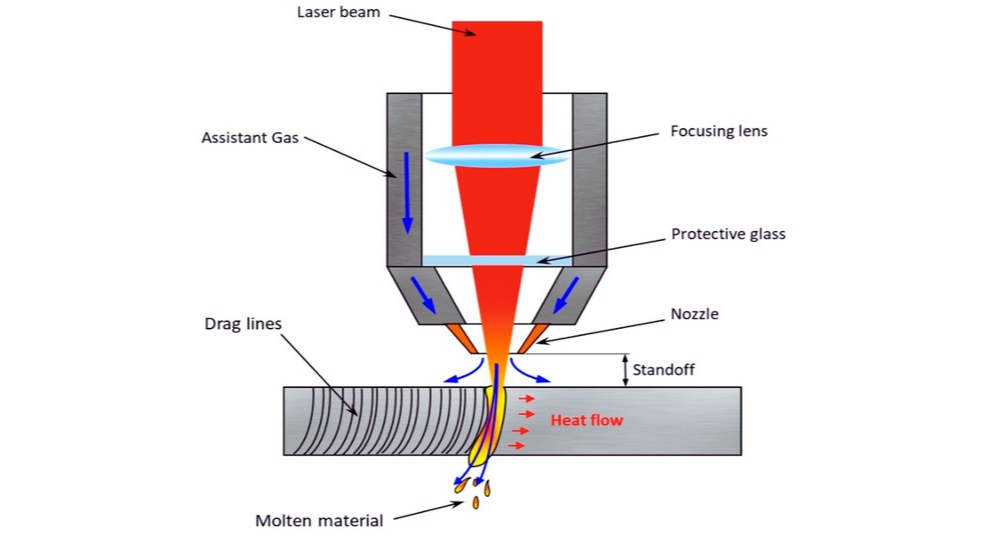

How does a laser cut

...

CNC

Introducing CNC

http://baike.baidu.com/l/ckUEPpWc

CNC machine tool is the abbreviation of computer numerical control machine tools, which is an automatic machine tool equipped with a program control system. The control system can logically process the program specified with control code or other symbolic instructions, and decode it, represent it with coded numbers, and input it into the numerical control device through the information carrier. After calculation and processing, various control signals are sent by the numerical control device to control the action of the machine tool, and the parts are automatically processed according to the shape and size required by the drawing.

http://baike.baidu.com/l/ckUEPpWc

CNC machine tool is the abbreviation of computer numerical control machine tools, which is an automatic machine tool equipped with a program control system. The control system can logically process the program specified with control code or other symbolic instructions, and decode it, represent it with coded numbers, and input it into the numerical control device through the information carrier. After calculation and processing, various control signals are sent by the numerical control device to control the action of the machine tool, and the parts are automatically processed according to the shape and size required by the drawing.

Conventional machine tools

Peculiarity

1. Strong adaptability to the processing object, adapt to the characteristics of single piece production of molds and other products, and provide a suitable processing method for the manufacture of molds;

2. High processing accuracy and stable processing quality;

3. It can carry out multi-coordinate linkage and process parts with complex shapes;

4. When the processed parts are changed, generally only need to change the CNC program, which can save production preparation time;

5. The machine tool itself has high precision and rigidity, and can choose a favorable processing amount and high productivity (generally 3~5 times that of ordinary machine tools);

6. The machine tool has a high degree of automation, which can reduce labor intensity;

7. It is conducive to the modernization of production management. CNC machine tools use digital information and standard code to process and transmit information, and use computer control methods, which lays the foundation for the integration of computer-aided design, manufacturing and management;

8. The quality requirements for operators are higher, and the technical requirements for maintenance personnel are higher;

9. High reliability.

CNC machine tools compared to traditional machine tools

1. It is highly flexible

Machining parts on CNC machine tools, mainly depends on the processing program, it is different from ordinary machine tools, it does not have to be manufactured, many molds, fixtures are replaced, and there is no need to readjust the machine tool frequently. Therefore, CNC machine tools are suitable for the frequent replacement of processed parts, that is, suitable for the production of single pieces, small batches of products and the development of new products, thereby shortening the production preparation cycle and saving a lot of process equipment costs.

2. High processing accuracy

The machining accuracy of CNC machine tool can generally reach 0.05-0.1mm, CNC machine tool is controlled in the form of digital signal, CNC device outputs a pulse signal every time, then the moving parts of the machine tool move a pulse equivalent (generally 0.001mm), and the reverse clearance of the machine tool feed transmission chain and the average error of the screw pitch can be compensated by the CNC device, therefore, the positioning accuracy of CNC machine tool is relatively high.

3. The processing quality is stable and reliable

Processing the same batch of parts, in the same machine tool, under the same processing conditions, using the same tool and processing program, the tool trajectory is exactly the same, the consistency of the parts is good, and the quality is stable.

4. High productivity

CNC machine tools can effectively reduce the machining time and auxiliary time of parts, and the spindle sound velocity and feed range of CNC machine tools are large, allowing machine tools to carry out powerful cutting with large stock removal volumes. CNC machine tools are entering the era of high-speed machining, and the rapid movement and positioning of moving parts of CNC machine tools and high-speed cutting processing have greatly improved productivity. In addition, when used in conjunction with the tool magazine of a machining center, it is possible to perform continuous processing of multiple processes on a single machine, reducing the turnaround time between processes of semi-finished products and improving productivity.

5. Improve working conditions

Before the CNC machine tool is adjusted, the program is entered and started, and the machine tool can be automatically and continuously processed until the end of processing. What the operator has to do is only the input of the program, editing, parts loading and unloading, tool preparation, observation of processing status, inspection of parts, etc., the labor intensity is greatly reduced, and the labor of the machine tool operator tends to be intellectually oriented. In addition, machine tools are generally combined, both clean and safe.

6. Modernize production management

The processing of CNC machine tools can accurately estimate the processing time in advance, and the tools and fixtures used can be standardized, modernized management, and easy to realize the standardization of processing information, which has been organically combined with computer-aided design and manufacturing (CAD/CAM), and is the basis of modern integrated manufacturing technology

1. Strong adaptability to the processing object, adapt to the characteristics of single piece production of molds and other products, and provide a suitable processing method for the manufacture of molds;

2. High processing accuracy and stable processing quality;

3. It can carry out multi-coordinate linkage and process parts with complex shapes;

4. When the processed parts are changed, generally only need to change the CNC program, which can save production preparation time;

5. The machine tool itself has high precision and rigidity, and can choose a favorable processing amount and high productivity (generally 3~5 times that of ordinary machine tools);

6. The machine tool has a high degree of automation, which can reduce labor intensity;

7. It is conducive to the modernization of production management. CNC machine tools use digital information and standard code to process and transmit information, and use computer control methods, which lays the foundation for the integration of computer-aided design, manufacturing and management;

8. The quality requirements for operators are higher, and the technical requirements for maintenance personnel are higher;

9. High reliability.

CNC machine tools compared to traditional machine tools

1. It is highly flexible

Machining parts on CNC machine tools, mainly depends on the processing program, it is different from ordinary machine tools, it does not have to be manufactured, many molds, fixtures are replaced, and there is no need to readjust the machine tool frequently. Therefore, CNC machine tools are suitable for the frequent replacement of processed parts, that is, suitable for the production of single pieces, small batches of products and the development of new products, thereby shortening the production preparation cycle and saving a lot of process equipment costs.

2. High processing accuracy

The machining accuracy of CNC machine tool can generally reach 0.05-0.1mm, CNC machine tool is controlled in the form of digital signal, CNC device outputs a pulse signal every time, then the moving parts of the machine tool move a pulse equivalent (generally 0.001mm), and the reverse clearance of the machine tool feed transmission chain and the average error of the screw pitch can be compensated by the CNC device, therefore, the positioning accuracy of CNC machine tool is relatively high.

3. The processing quality is stable and reliable

Processing the same batch of parts, in the same machine tool, under the same processing conditions, using the same tool and processing program, the tool trajectory is exactly the same, the consistency of the parts is good, and the quality is stable.

4. High productivity

CNC machine tools can effectively reduce the machining time and auxiliary time of parts, and the spindle sound velocity and feed range of CNC machine tools are large, allowing machine tools to carry out powerful cutting with large stock removal volumes. CNC machine tools are entering the era of high-speed machining, and the rapid movement and positioning of moving parts of CNC machine tools and high-speed cutting processing have greatly improved productivity. In addition, when used in conjunction with the tool magazine of a machining center, it is possible to perform continuous processing of multiple processes on a single machine, reducing the turnaround time between processes of semi-finished products and improving productivity.

5. Improve working conditions

Before the CNC machine tool is adjusted, the program is entered and started, and the machine tool can be automatically and continuously processed until the end of processing. What the operator has to do is only the input of the program, editing, parts loading and unloading, tool preparation, observation of processing status, inspection of parts, etc., the labor intensity is greatly reduced, and the labor of the machine tool operator tends to be intellectually oriented. In addition, machine tools are generally combined, both clean and safe.

6. Modernize production management

The processing of CNC machine tools can accurately estimate the processing time in advance, and the tools and fixtures used can be standardized, modernized management, and easy to realize the standardization of processing information, which has been organically combined with computer-aided design and manufacturing (CAD/CAM), and is the basis of modern integrated manufacturing technology

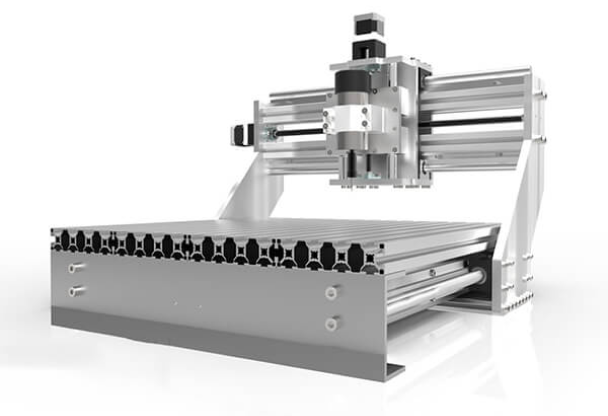

1. CNC milling machine

Numerical control milling machine is a machine that has similarities with numerical control milling machines. However, it is usually used to process softer materials, and its accuracy may be slightly lower than that of CNC milling machines.

A typical CNC milling machine consists of a mechanical base, a power supply, a spindle, a stepper driver, a stepper motor and a controller. Compared with traditional processing methods, CNC milling machines have the advantages of improving productivity, improving accuracy and reducing material waste, so that products can be produced faster.

Similar to CNC milling machines, CNC milling machines are available in a variety of shaft configurations, ranging from three to six axes. Entry-level CNC milling machines typically utilize a 3-axis system to carve the workpiece into the desired shape. In addition, rotary tool accessories (4 axes) can be purchased separately for machining curved workpieces.

CNC milling machines excel at using computer numerical control to mill spindles and machine paths, enabling the ability to work on a variety of materials such as aluminum, steel, plastic, wood, composite materials and foam to achieve the desired final design and shape.

Numerical control milling machine is a machine that has similarities with numerical control milling machines. However, it is usually used to process softer materials, and its accuracy may be slightly lower than that of CNC milling machines.

A typical CNC milling machine consists of a mechanical base, a power supply, a spindle, a stepper driver, a stepper motor and a controller. Compared with traditional processing methods, CNC milling machines have the advantages of improving productivity, improving accuracy and reducing material waste, so that products can be produced faster.

Similar to CNC milling machines, CNC milling machines are available in a variety of shaft configurations, ranging from three to six axes. Entry-level CNC milling machines typically utilize a 3-axis system to carve the workpiece into the desired shape. In addition, rotary tool accessories (4 axes) can be purchased separately for machining curved workpieces.

CNC milling machines excel at using computer numerical control to mill spindles and machine paths, enabling the ability to work on a variety of materials such as aluminum, steel, plastic, wood, composite materials and foam to achieve the desired final design and shape.

Apply

CNC milling machines are highly versatile machines suitable for cutting complex shapes and are used in a wide variety of applications, including: Carved wood furniture, Decorative, molding, Interior and exterior decoration, Door carving, placard, Musical instrument

CNC milling machines are highly versatile machines suitable for cutting complex shapes and are used in a wide variety of applications, including: Carved wood furniture, Decorative, molding, Interior and exterior decoration, Door carving, placard, Musical instrument

2. CNC drilling machine

CNC drilling machines are automatic drilling machines that can punch precise and complex holes in the workpiece. They are equipped with a mechanically rotating drill bit that can penetrate the workpiece radially to create a cylindrical hole. The design of the drill bits causes scrap material (called chips) to fall off the workpiece. There are several types of drill bits available for different applications, including screw machine bits, deep hole bits, centering bits and clamp reamers.

CNC drilling machines automatically control parameters such as spindle speed, feed speed, cut rate and depth of cut based on instructions provided by the CNC programmer. These machines can process materials at much higher speeds than traditional manual drilling techniques. These machines are equipped with intelligent tool exchange and positioning technology that helps increase productivity.

CNC drilling machines are automatic drilling machines that can punch precise and complex holes in the workpiece. They are equipped with a mechanically rotating drill bit that can penetrate the workpiece radially to create a cylindrical hole. The design of the drill bits causes scrap material (called chips) to fall off the workpiece. There are several types of drill bits available for different applications, including screw machine bits, deep hole bits, centering bits and clamp reamers.

CNC drilling machines automatically control parameters such as spindle speed, feed speed, cut rate and depth of cut based on instructions provided by the CNC programmer. These machines can process materials at much higher speeds than traditional manual drilling techniques. These machines are equipped with intelligent tool exchange and positioning technology that helps increase productivity.

Apply

CNC drilling machines are used in various industries, including:

Automobile manufacturing, shipbuilding, spaceflight, Construction machinery, Mold making, Woodworking and furniture making

CNC drilling machines are used in various industries, including:

Automobile manufacturing, shipbuilding, spaceflight, Construction machinery, Mold making, Woodworking and furniture making

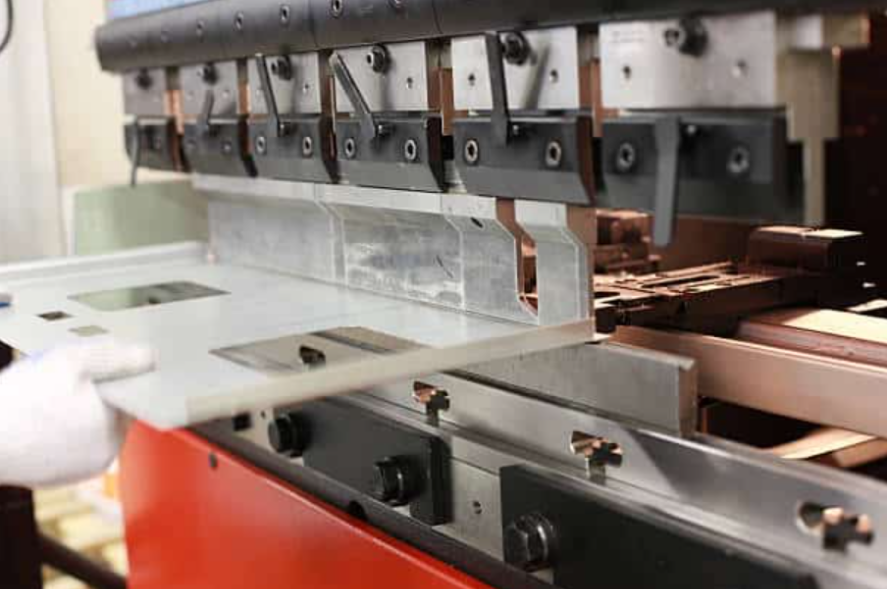

4. CNC milling machine

CNC milling machines utilize high-speed rotating multi-point cutting tools to precisely remove material from workpieces that are usually held in place to form the desired shape.

CNC milling machines utilize high-speed rotating multi-point cutting tools to precisely remove material from workpieces that are usually held in place to form the desired shape.

5. CNC plasma cutting machine

CNC plasma cutting machines provide precise cutting. It does this by utilizing a discharge arc, similar to a plasma torch, that ionizes the air and melts the material at the point of contact with the arc.

CNC plasma cutting machines provide precise cutting. It does this by utilizing a discharge arc, similar to a plasma torch, that ionizes the air and melts the material at the point of contact with the arc.

6. CNC laser cutting machine

CNC laser cutting machines and CNC plasma cutting machines have similar ability to cut tough materials. However, unlike plasma cutters that utilize ionized gas, CNC laser cutters use highly focused laser beams.

CNC laser cutting machines and CNC plasma cutting machines have similar ability to cut tough materials. However, unlike plasma cutters that utilize ionized gas, CNC laser cutters use highly focused laser beams.

7. CNC discharge processing machine

Numerical control discharge machines (EDMs), often referred to as spark CNC machines, use electrical sparks to manipulate and shape materials. This EDM process can also be called wire burning, die opening, spark machining or spark corrosion.

Numerical control discharge machines (EDMs), often referred to as spark CNC machines, use electrical sparks to manipulate and shape materials. This EDM process can also be called wire burning, die opening, spark machining or spark corrosion.

8. CNC grinding machine

CNC grinding machines use abrasive tools to achieve smooth and precise finish of processed products. It is commonly used in drive shafts, camshafts, ball bearings and other workpieces that require a precise and polished surface.

CNC grinding machines use abrasive tools to achieve smooth and precise finish of processed products. It is commonly used in drive shafts, camshafts, ball bearings and other workpieces that require a precise and polished surface.

12. Automatic tool change

CNC machine The Automatic Tool Changer (ATC) is a variant of various types of CNC machines. This feature allows for quick and efficient replacement of cutting tools within a CNC machine. It allows for seamless transitions between different types of cutting tools or replacement of damaged or worn tools. The ability to automate the tool change process can increase production speed and minimize machine downtime.

CNC machine The Automatic Tool Changer (ATC) is a variant of various types of CNC machines. This feature allows for quick and efficient replacement of cutting tools within a CNC machine. It allows for seamless transitions between different types of cutting tools or replacement of damaged or worn tools. The ability to automate the tool change process can increase production speed and minimize machine downtime.

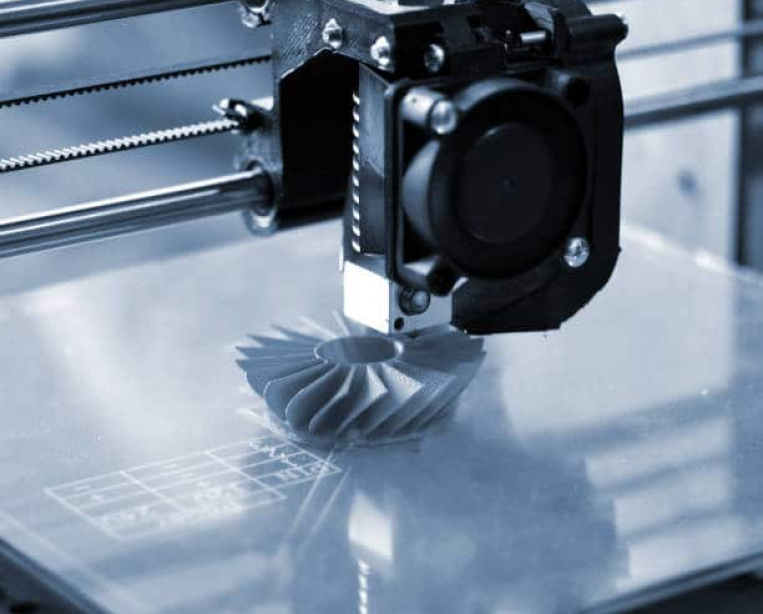

11. 3D printers

CNC machines are known as 3D printers that are used to create three-dimensional workpieces by layering materials based on digital designs or models. To prepare the 3D design, the operator uses CAD software, which is then sliced into 2D layers by CAM software to generate the commands needed to control the printing process.

CNC machines are known as 3D printers that are used to create three-dimensional workpieces by layering materials based on digital designs or models. To prepare the 3D design, the operator uses CAD software, which is then sliced into 2D layers by CAM software to generate the commands needed to control the printing process.

9. CNC water jet cutting machine

CNC water jet cutting machines, as the name suggests, utilize high-pressure water jets, and in some cases additional abrasives, to efficiently cut a variety of materials. These waterjet cutters can handle both 2D and 3D cuts and are good at cutting high thickness materials.

CNC water jet cutting machines, as the name suggests, utilize high-pressure water jets, and in some cases additional abrasives, to efficiently cut a variety of materials. These waterjet cutters can handle both 2D and 3D cuts and are good at cutting high thickness materials.

10. CNC take-and-place robot

In the manufacturing industry, pickup and drop robots have gained widespread popularity because they are specifically designed for repetitive tasks. These CNC machines eliminate the need to manually handle workpieces, reducing human interference and associated risks.

In the manufacturing industry, pickup and drop robots have gained widespread popularity because they are specifically designed for repetitive tasks. These CNC machines eliminate the need to manually handle workpieces, reducing human interference and associated risks.

Machine type

3. CNC lathe

The CNC lathe uses a single point cutting tool to remove material from the rotating workpiece and shape it to the desired specifications. Compared with manual lathes, CNC lathes improve the speed and accuracy of finished product manufacturing.

The CNC lathe uses a single point cutting tool to remove material from the rotating workpiece and shape it to the desired specifications. Compared with manual lathes, CNC lathes improve the speed and accuracy of finished product manufacturing.

Laser Cutter

3.Make sure the machine ,material